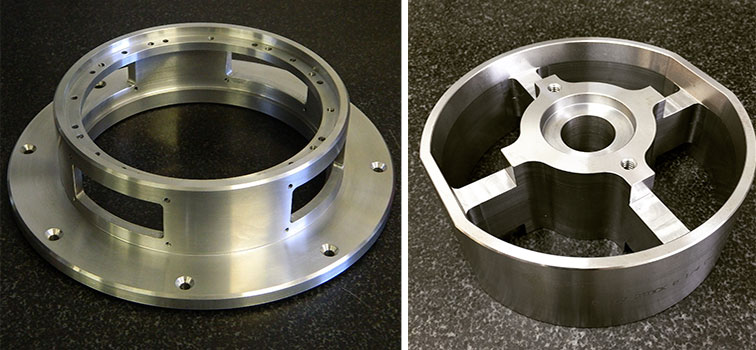

Turning Capabilities

Multi-task turning centers equipped with Y-Axis, Sub-Spindles, and Live tooling enable us to complete complex parts in one setup. This eliminates the need for multiple operations, and part handling therefore saving time and cutting cost.

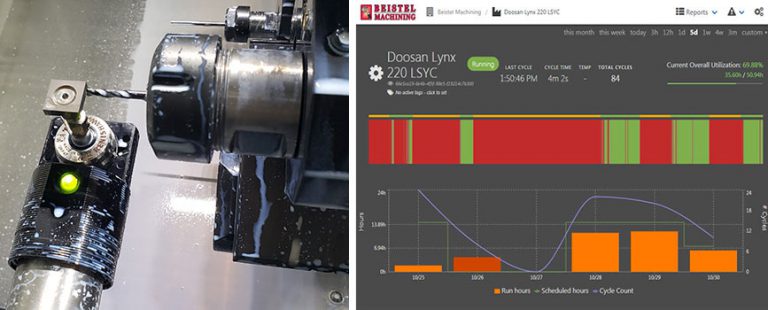

High Volume Production

Fully automated, bar fed lathes with automatic tool check and remote monitoring allow us to run unattended 24 hour production for faster turnaround times on high volume orders. Send your drawings and allow us to prepare a quote for your turning needs!