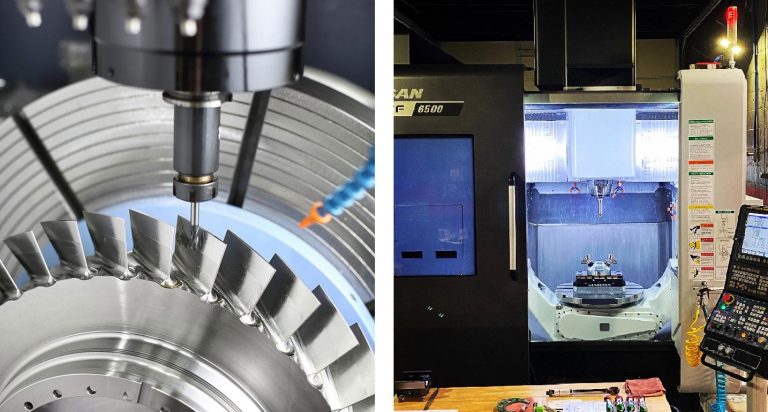

Milling Capabilities

Our CNC Milling department offers a variety of 3, 4, and 5-Axis machining centers equipped with the latest technology to increase accuracy and decrease turnaround time. Proficiency in high performance machining and multi-cavity fixturing allows us to machine your parts faster and with greater precision.

High Volume Production

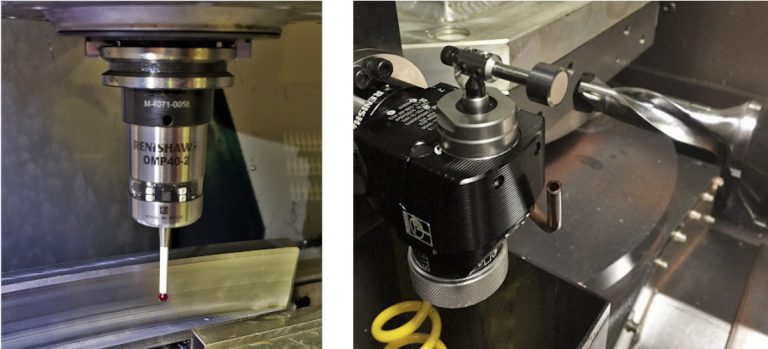

High volume production orders can easily be achieved with our High-Speed spindles, fast rapids, Renishaw probing systems, and pallet changers. Contact us today to see how we can help you cut cost, meet deadlines, and improve your supply chain!

How does this benefit you?

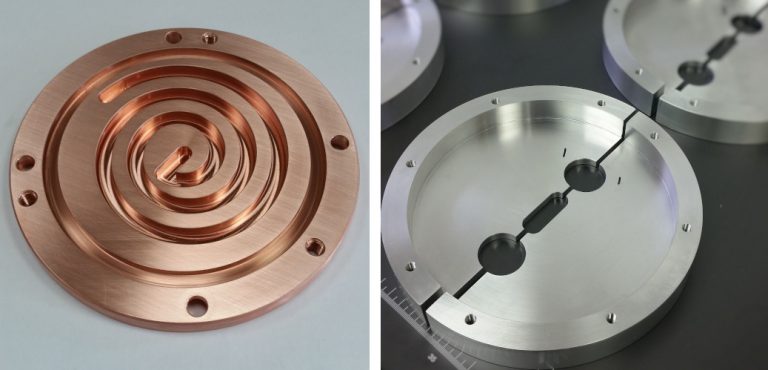

Simultaneous 5-axis machining allows us to manufacture complex components that are unachievable by other machining methods.

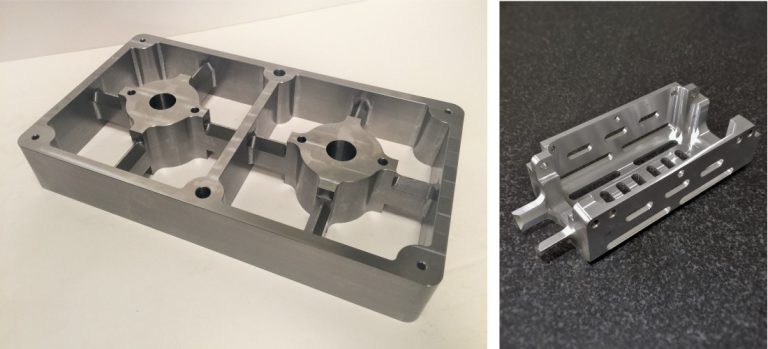

High volume orders can quickly and efficiently be met with multi-cavity fixturing and workholding.

While maintaining quality, our equipment’s high metal removal rates reduce cost and decrease turnaround times.

Precision, quality, and tight tolerances are maintained during the machining cycle with in-process tool and part probing.

From small to large, our 5-axis department can process parts up to 30” in diameter.

Tight tolerances and surface finish requirements are consistently achieved with our state-of-the-art machining centers.